Drone-based GIS functionality to support business functions, such as mapping for mine planning and inspections, are important. Some drone GIS solutions also tout stockpile measurement as a feature, however, these “solutions” require a substantial amount of manual work and are prone to misuse. With Stockpile Reports™, we measure Every Pile in the bulk materials ecosystem to give answers you need in real-time. Take any image and we give you the answer.

Stockpile Reports is the only automated, controlled, and scalable third-party solution for managing bulk materials inventory. We have the only third-party Verification and Scoring stockpile measurement process in the world. We verify your inventory whether you capture imagery with planes, drones, phones, or installed cameras. Our patented technology ensures precision with reports that auto-correct obstructions, provide an objective surface score, and measure confidence in toe and base calculations. The future is continuous automated real-time inventory measurements that enable great decisions at every level of business operations: inventory management, plant operations, and logistics. Stockpile Reports is the only vertically-focused business application capable of digitizing your entire bulk materials supply chain.

The Problem With Drone GIS Solutions

CEO and Founder, David Boardman, is passionate about Stockpile Reports’ easy-to-scale, comprehensive solution because bulk materials measurement is a business problem that won’t go away.

“The challenges of bulk materials inventory are real. You can’t put a bar code on a pile of rock. “Do it yourself” counts where Bobby flies the drone result in measurements that are not consistent or independent. Without controls over assumptions like density factors and base planes, the reliability of that measurement goes out the door. If I was a CFO, I wouldn’t want to bet my job on financials that didn’t have a verified report! And with Stockpile Reports, anyone or any robot can take a picture and get the answer, no knife and fork GIS nonsense.”

We frequently help customers transitioning from a drone GIS solution. Often, pile measurement services are marketed as a way to combine internal GIS requirements and inventory management to save money. What is not discussed is the “knife and fork” to make it work, a manual pile identification and review. Our studies show drone GIS solutions take nearly 20X more internal manpower to use than Stockpile Reports, from fieldwork and measurement to time spent in the back office on inventory variances and disputes.

The other dirty secret is that because the drone GIS measurement process is internally managed and requires a human interface, the results can be manipulated, putting the reliability of your financial statements at risk. Stockpile Reports takes a fraction of the time to execute because our proprietary digitization technology does the work for you. And inventory is reported with consistency, control, and trust.

How is Stockpile Reports NOT a Drone GIS Tool?

#1 Automation

No clicking on piles required: Automation drives consistency because Stockpile Reports’ advanced algorithms convert images of stockpiled bulk materials into accurate and precise measurements. Our method removes internal bias and manual errors, establishing the foundation for a consistent and reliable process to support financial values. Stockpile toes and surfaces are automatically calculated and scored. Obstructions are systematically identified and addressed.

#2 Control

Independent reports come from a controlled process: Company policies for density factors and specifications about products and piles are highly controlled as to when and who modifies these subjective assumptions. If you or someone on the team doesn’t like the answer – sorry, you can’t change it! We manage technical inquiries with a transparent, audited, dispute resolution process. These industry-leading controls are why Stockpile Reports is classified as a third-party service by major audit firms.

#3 Risk Management

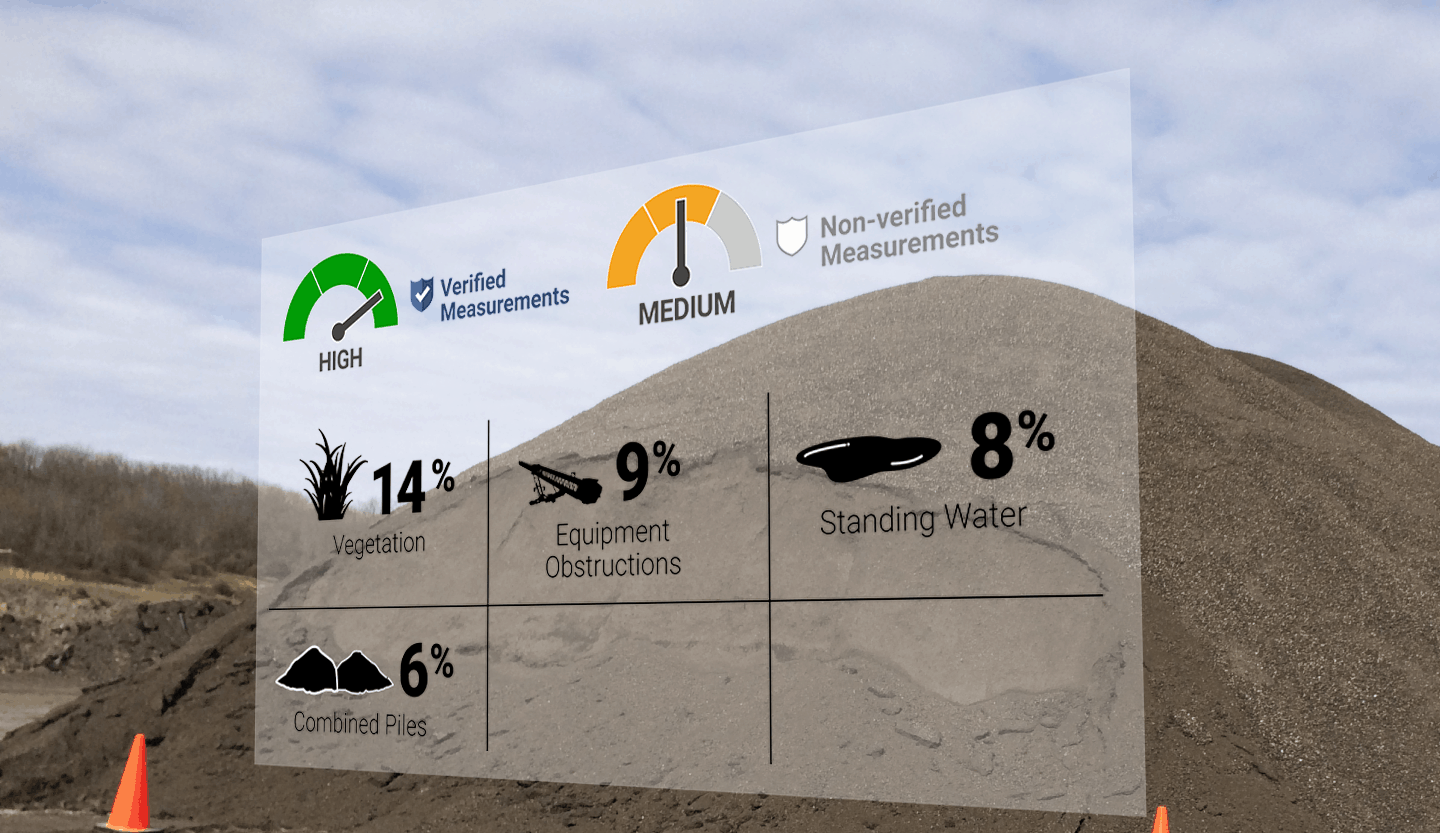

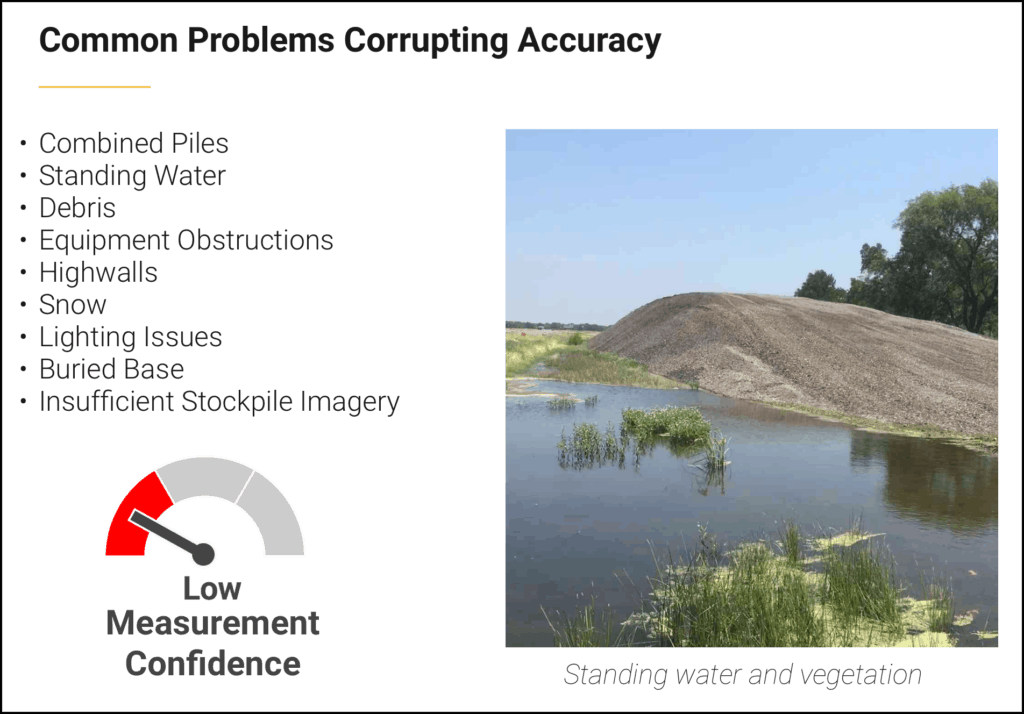

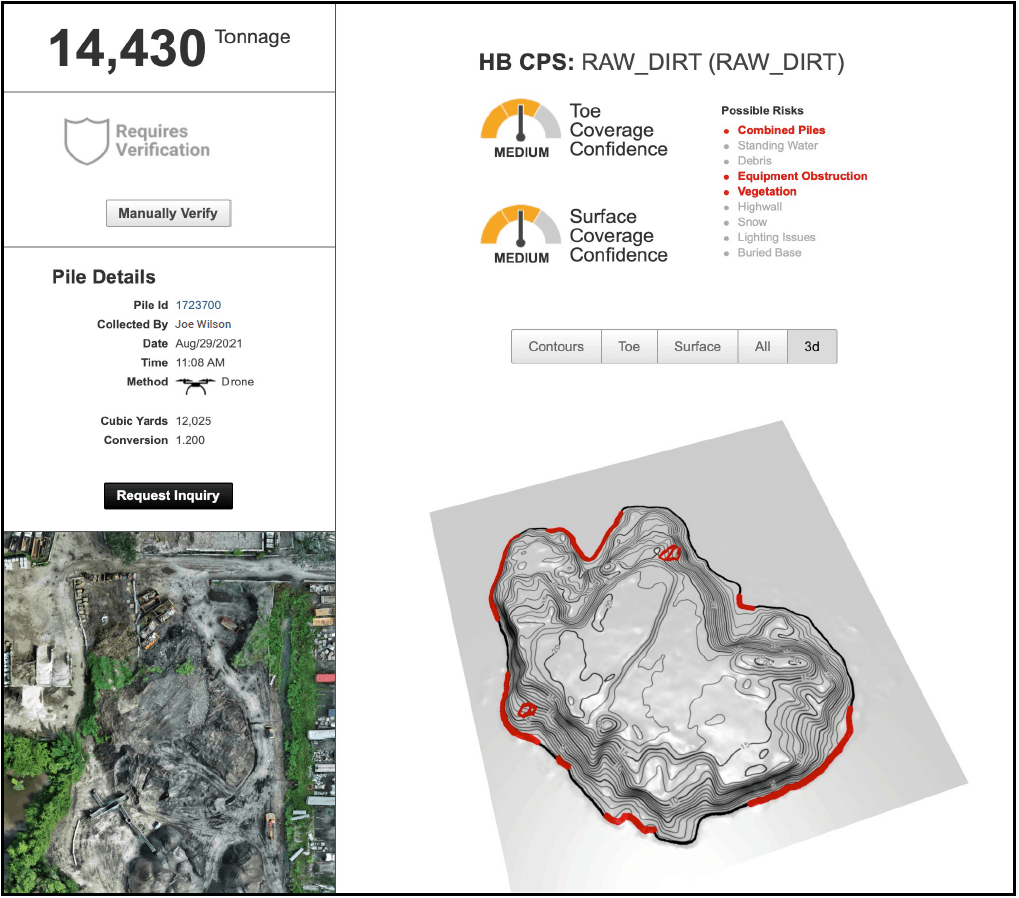

Measurements are verified, which adds a higher level of control: Stockpile Reports identifies the risks in each measurement, independently evaluating more than a dozen common problems corrupting the accuracy of stockpile measurements. Sample risks include combined piles, vegetation, standing water, equipment obstructions, and more. If a measurement is not sufficient, we tell you! And we don’t publish reports that are not reliable for financial reporting. The stakes are too high. When risks are detected, we require manual verification and resolution of problematic conditions before we issue a report.

#4 Confidence Scoring

Our reports can be trusted: Confidence scoring is a unique solution to Stockpile Reports. Our patented technology ensures precision with reports that auto-correct obstructions, provide an objective surface score, and measure confidence in toe and base calculations. For example, the biggest contributor to the volume of a pile is the determination of the base plane and our algorithms assess the accuracy of this measurement. No other stockpile measurement technology addresses this financial statement risk.

Stockpile Reports helps customers reduce inventory write-offs from unacceptable levels, many exceeding 40%, while also creating a scalable, controlled, and efficient process that doesn’t deplete internal resources or create delays with financial reporting disputes. Early detection of transactional errors and improved decisions over inventory planning with Stockpile Reports has saved customers tens of millions in inventory losses. Stockpile Reports’ customers understand this value. As one member of an international road construction group expressed, “the more we measure, the better we get”.

About Stockpile Reports

Stockpile Reports is the first vertically integrated service for logistics and inventory management of bulk materials at scale, digitizing images of bulk materials to solve problems with accurate perpetual inventory and supply chain planning. Every Pile, Any Time.

Stockpile Reports uses EveryPoint, a spatial computing platform that supports infinitely scalable data collection and processing for the next generation of spatial computing applications and services. EveryPoint has been building spatial computing solutions at scale, ranging from rapid 3D processing of massive image datasets to global logistics and inventory management solutions. Use EveryPoint to bring spatial computing to your applications and services.