Insights from Monthly Drone Measurements

Face it, your team at most is measuring your inventory by drone monthly. The insights from drone flights are only as good as the time from the last flight. The value for your operations team is low once the data is a few days old. However, the insights are invaluable to the finance team.

Below are the actionable insights that your operations and finance team can use from monthly flights:

1. Inventory Updates to Make Adjustments

Your finance team most likely only needs to report official inventory once or twice a year. However, monthly measurements allow for smaller adjustments to the P&L statement. Larger unexpected adjustments from a month-long production window also provides insights into a deeper problem such as missing scale tickets, theft, or improperly calibrated scales. For operations, this gives them a chance to track down issues causing unexpected loss before the P&L adjustment becomes too big that it triggers a painful root cause analysis (RCA) with upper management.

2. Updated Maps for Planning

How old is that map of your site on Google Maps? We bet it’s old! Monthly drone flights of your site provide updated site maps that are useful in several ways. You can mark up the map with products to hand out to truck drivers at the scales to ensure they know where they are going. You can see what your piles and high walls look like as of today to come up with a plan for additional blasting and storage of materials. You can also identify potential water drainage issues that were hard to see from the ground.

Insights from Daily Measurements

Operations managers know that time is of the essence when it comes to making decisions about production. Monthly snapshots of inventory just won’t cut it for a business where plans can change on a daily basis. With an iPhone solution, anyone on site can measure any pile daily to get actionable information for production and sales. In the near future, drones will also be deployed from base stations at your sites autonomously capturing daily flights of your inventory.

Here are a few insights you start using today from daily measurements:

3. Gain Insight on Unexplained Loss

Are specific piles at your sites experiencing unexplained loss between monthly flights? The best way to determine the source of the loss is to perform daily measurements and find where the source of the inventory discrepancy is coming from. You may find that your loader operator is spilling excess amounts of material in transit to the plant or dump trucks. You may also find that the volume of your densities are incorrect due to excess moisture in your piles. The best way to determine the issue is through repeated measurement and analysis.

4. Verify Daily Production

Is your team aiming to achieve a specific daily production number for a specific product? With the iPhone, a pile can be measured at the start and end of the day to calculate the total amount produced. This helps avoid incorrect assumptions based on belt scales. Also, if your team is aiming to produce a specific total tonnage of one product before changing the screening plant to a different spec, you can keep daily tabs and ensure you do not over or underproduce before retooling your plant.

5. Verify Inventory for Sales

The sales team relies on a perpetual inventory system to verify how much material they have on hand to sell. However, perpetual inventory systems can be notoriously wrong due to the timing of sales ticket and production numbers being entered into the system. Using an iPhone or drone, a sales team member can easily go on-site and verify the inventory of a specific pile on the day they need it. This also reduces friction between sales and operations because the material won’t be sold that isn’t available.

Insights from Hourly Measurements

The holy grail of measurement data for operations managers is constant measurement. Every hour, every 15 minutes, on-demand. Being able to have inventory numbers of what is on hand right now allows for on the fly decisions to keep a plant running at optimal efficiency. Achieving this measurement frequency means looking to tools beyond the drone or iPhone. Camera systems permanently installed on buildings, machinery, hard hats, etc. coupled with streamlined computer vision systems are powering the future of minute by minute inventory numbers. Here are a few insights that can be driven from hourly measurements.

6. Measure Actual Tons Per Hour (TPH)

Production managers set up goals for their team to hit, such as tons per hour from the plant, trucks per hour dispatched, hours of downtime, etc. Tons per hour is the number one key indicator of how efficient your plant is operating. Plant operators have to rely on belt scales or bucket counts which give a ballpark production number. Using an iPhone or fixed camera system, a plant manager can get hourly updates on how the material is actually being produced. This allows for hourly adjustments to ensure target production numbers are being achieved.

7. Power Streamlined Logistics

Are you a ready mix, asphalt, or cement producer? Do you daily buy small amounts of material to feed your plants? With fixed camera systems, your inventory can be measured hourly to determine the amount of material on hand for production. Essentially, your stockpiles become fuel gauges that are constantly monitored. When your inventory of a specific product runs low, automatic dispatching notifies the producer to ship more. You can essentially eliminate the daily task of monitoring and purchasing materials.

8. Eliminate Inventory Errors

Imagine having complete inventory numbers across your entire site every hour. Perpetual inventory would be run off camera measurement systems instead of scale and production ticket merges. Instead of always having an inventory a day or more behind in your accounting software, you would have hourly inventory updates. You can catch errors as they happen and make adjustments. No more P&L adjustments ever.

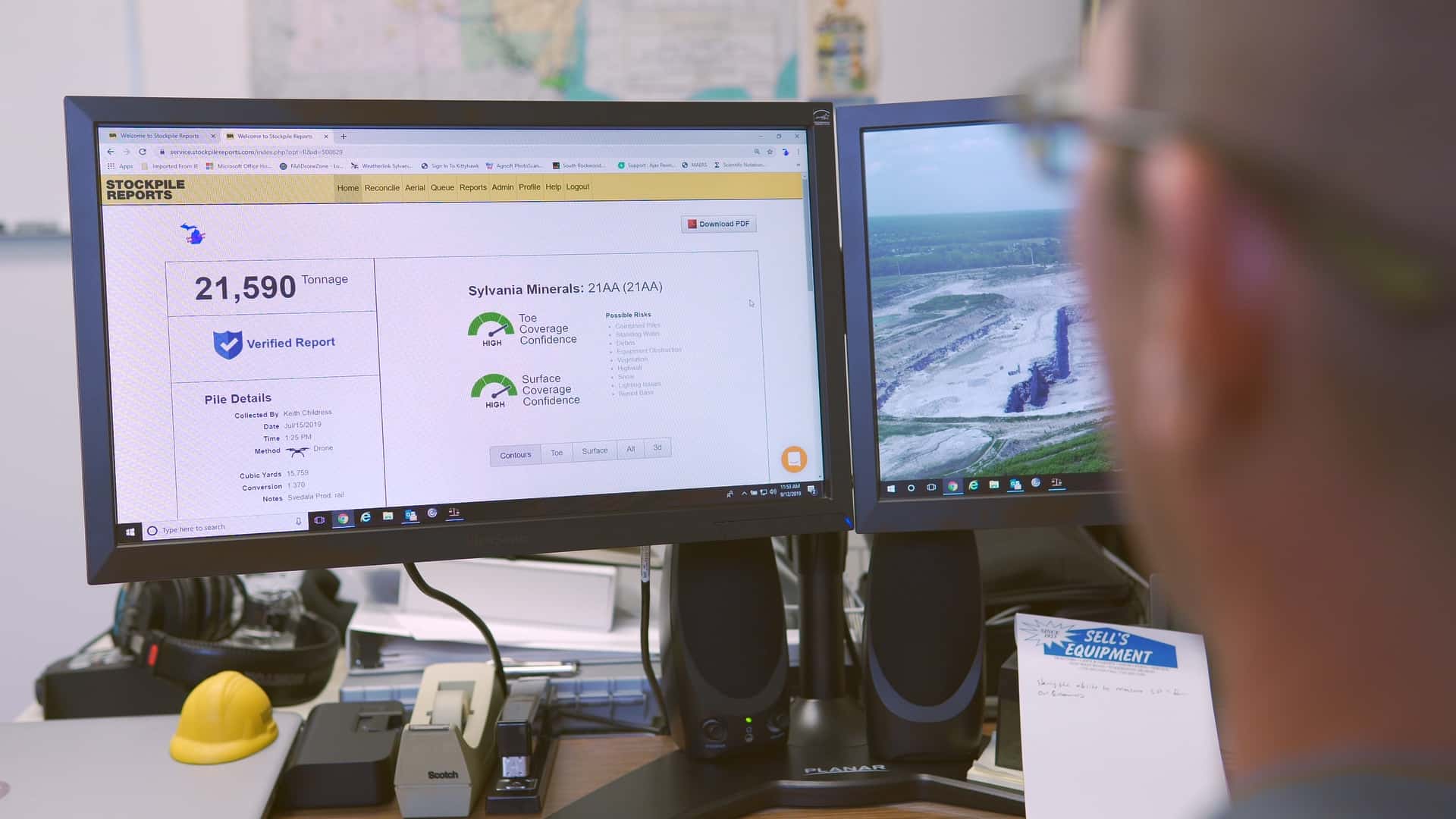

Intuitive Solutions for Better, More Strategic Decision Making

Stockpile Reports is a trusted solution in the industry. Our solution provides you with actionable insights that you can use today to improve your business, maximize profit, and alleviate painful write-offs. The data is trustworthy, third-party compliant, and verifiable. If you are ready to take your business to the next level and make smarter, more strategic business decisions, contact us for a demo and trial of the product.